Our products

Epiluvac products are normally delivered as complete systems including reactor module, gas delivery system, process control, safety system, installation, and commissioning. Each system is tested extensively before shipment, and once installed the delivery also includes all necessary customer trainings for operation and maintenance.

CVD epitaxy reactors for SiC and GaN

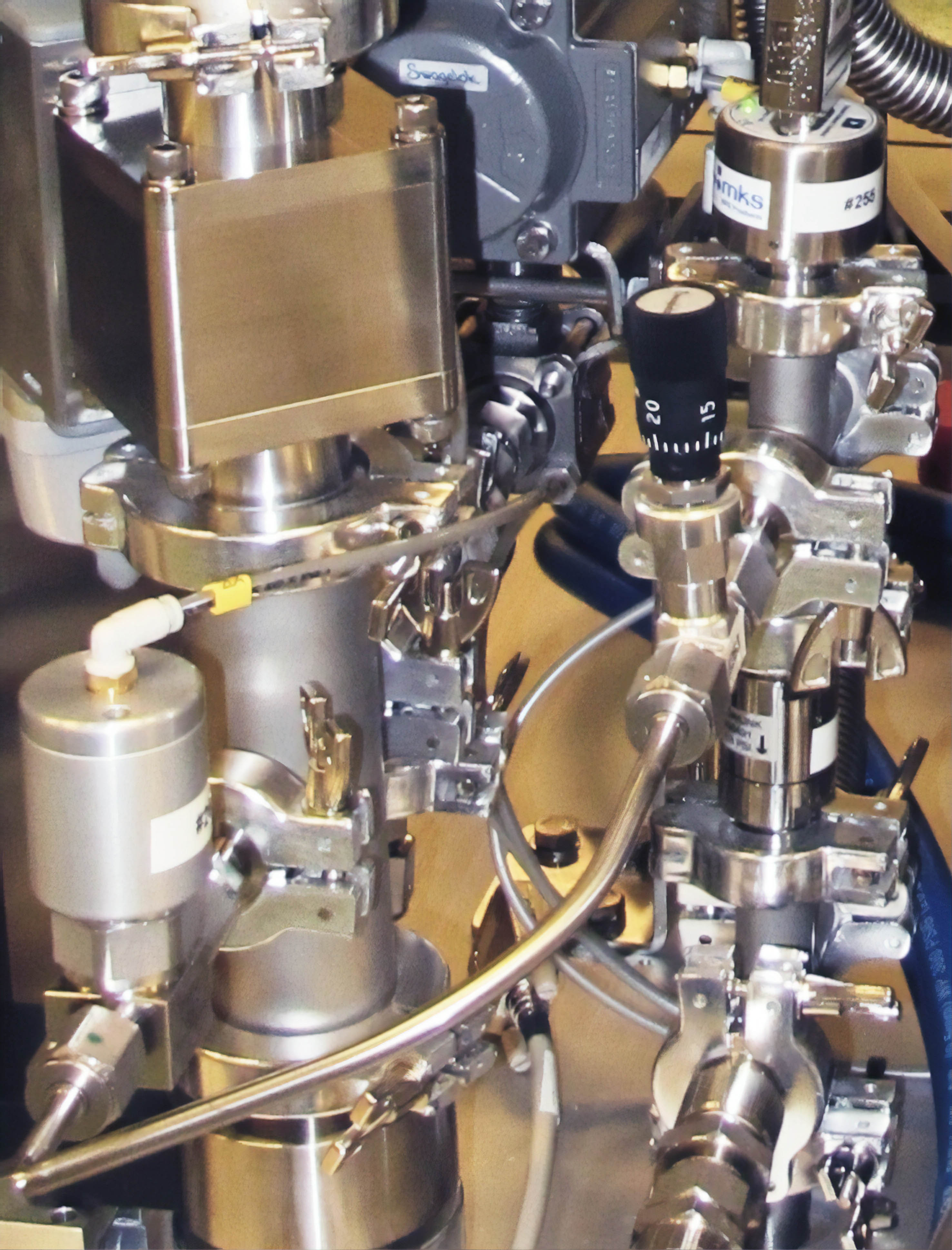

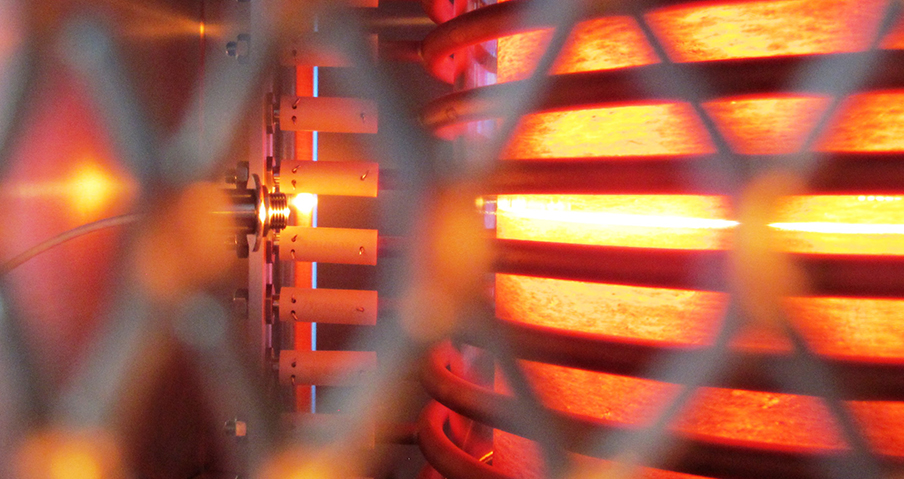

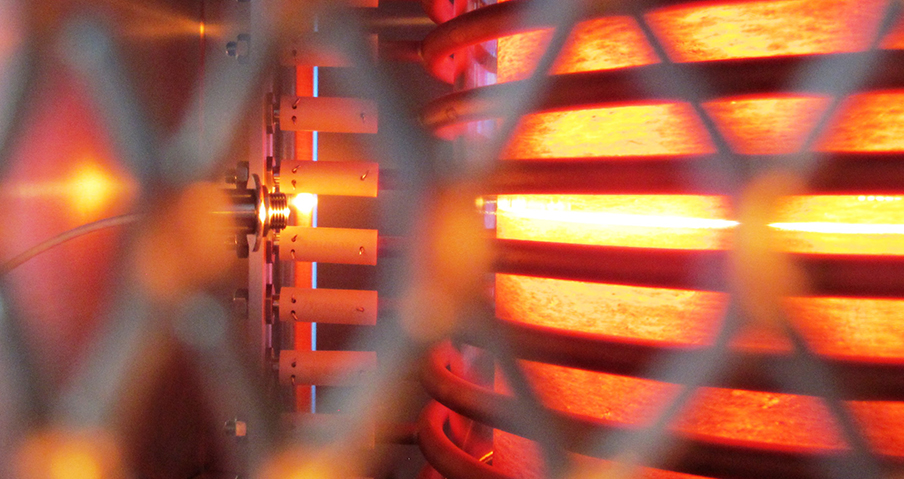

SiC epitaxy system

Epiluvac ER3-C1

• Up to 200 mm (8”) wafer diameter.

• Excellent uniformity through hot-wall topology.

• Advanced dynamic gas flow control for optimum growth rate and doping uniformity.

• Excellent temperature profile with multiple heating zones.

• Quartz-free and intended for chlorinated processes.

• Hot wafer loading/unloading in a clean inert atmosphere minimizes particle contamination and extends the lifetime of graphite parts.

• Modular design with two, three or four reactors in a cluster configuration. Each reactor is optimized for a certain growth step.

• Wafer transportation between the reactors in a controlled environment.

• Up to 1800 °C.

• Suitable for low/medium volume production and R&D.

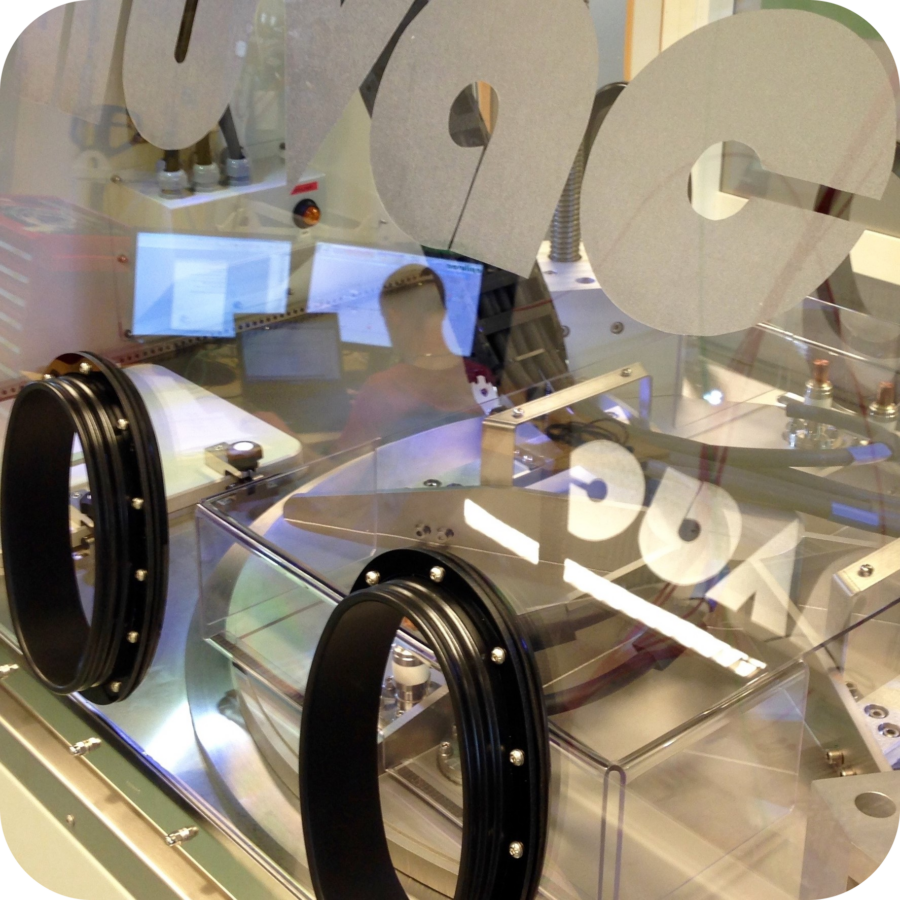

Epiluvac EPI 1000-C

• Hot-wall CVD for excellent uniformity.

• Up to 150 mm substrate diameter

• Single-wafer and manual loading.

• Well suited for R&D.

GaN epitaxy system

Epiluvac ER3-N1

• The GaN version of the above ER3-C1 system.

• Optional in-situ monitoring.

• Patented temperature control to minimize wafer bow.

• Exceptional process results. See https://c3nit.se/

PVT crystal growth systems for SiC

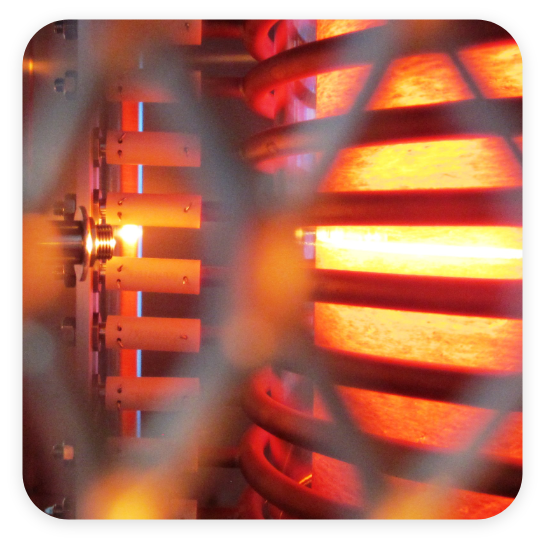

SiC crystal growth furnace – Epiluvac SB3-C1

• Based on well established PVT/sublimation principles

• Cost efficient design based on proven modules

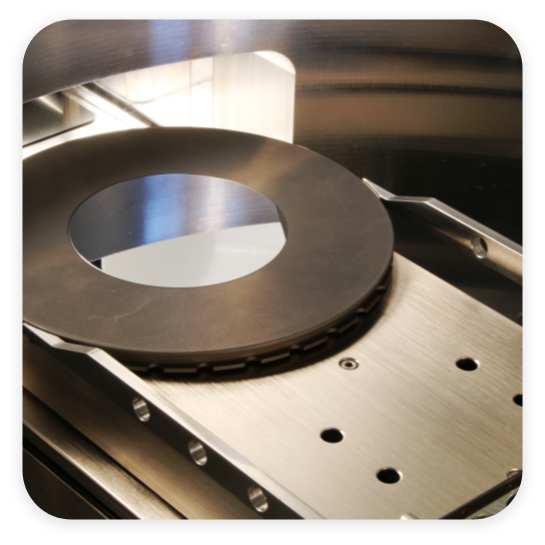

Customized systems for special needs

The engineering team at Epiluvac carries decades of experience from designing high performance material deposition systems to specific customer needs. This, combined with our range of standardized and well proven building blocks enables us to offer safe, efficient and priceworthy solutions adapted to customer needs. Typical applications include ultra-high vacuum, extremely high temperature (2600 °C), complex gas mixture or high flexibility for research requirements.